While cutting through the laser cutters, there are certain specifications and things to keep in mind. If you do not know what materials should not be used with a laser cutter, you must know about them in detail.

There are a few materials you shouldn’t cut with a laser because of their substance make-up or chemical composition. These materials include:

- Cowhide and fake calfskin that contains chromium (VI)

- Carbon filaments (Carbon)

- Polyvinyl chloride (PVC)

- Polyvinyl butyral (PVB)

- Polytetrafluoroethylene (PTFE/Teflon)

- Beryllium oxide

- ABS plastic

- Coated Carbon Fiber

There are certain materials like the incandescent lamp (bromine, iodine, fluorine, chlorine and astatine).

There are materials that require certain care if you cut them with the laser cutter. They are likely to get fit with the laser cutter, but still, there are some things to keep in mind. There are certain materials that require care while dealing with them during the process of laser cutting. They usually include:

- Chromium

- Manganese

- Nickel

- Lead

- Cobalt

The materials that are mentioned above require certain care and protection while using. Further, we will look at some of the other things you should know about laser cutting.

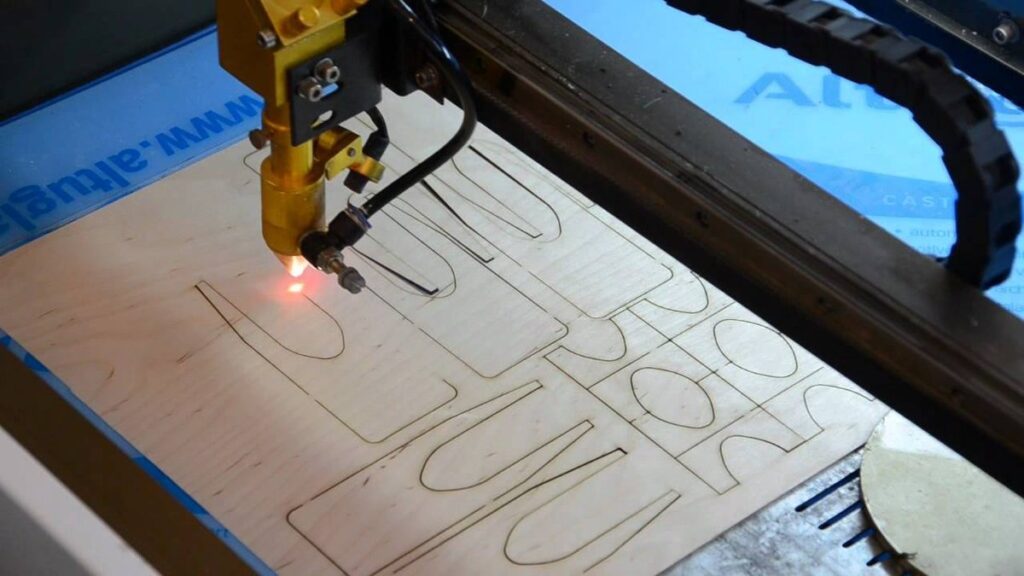

What is the Best Wood for laser cutting?

Source: all3dp.com

The laser cutting is usually used by many carpenters for cutting different kinds of objects. The best wood for laser cutting relies upon your objective.

Cardboard

Assuming you are in the beginning phases of prototyping, it is always a suggestion: cardboard. You don’t always jump on doing the hardest part when you start something. When you are thinking of starting, you must know that cardboard is considered one of the best wood for laser cutting.

The cardboard is modest, simple to slice and simple to drop by. It can likewise be engraved on. I wouldn’t suggest it for later phases of prototyping or a result, in any case. Engraving becomes easier on cardboard, and that’s the reason why cardboard is a good material for laser cutting.

Plywood

Many materials are used in laser and cutting. One is the best and way easy to cut plywood in the later phases of prototyping, or on the other hand, in the event that you intend to make something that doesn’t have to look outwardly aesthetic. Plywood is more grounded than cardboard, and it is still simple to cut; however, it’s not as modest or simple to find. Plywood is considered the perfect option for cutting through a laser cutter as it is fragile and does not make the machine take a lot of loads.

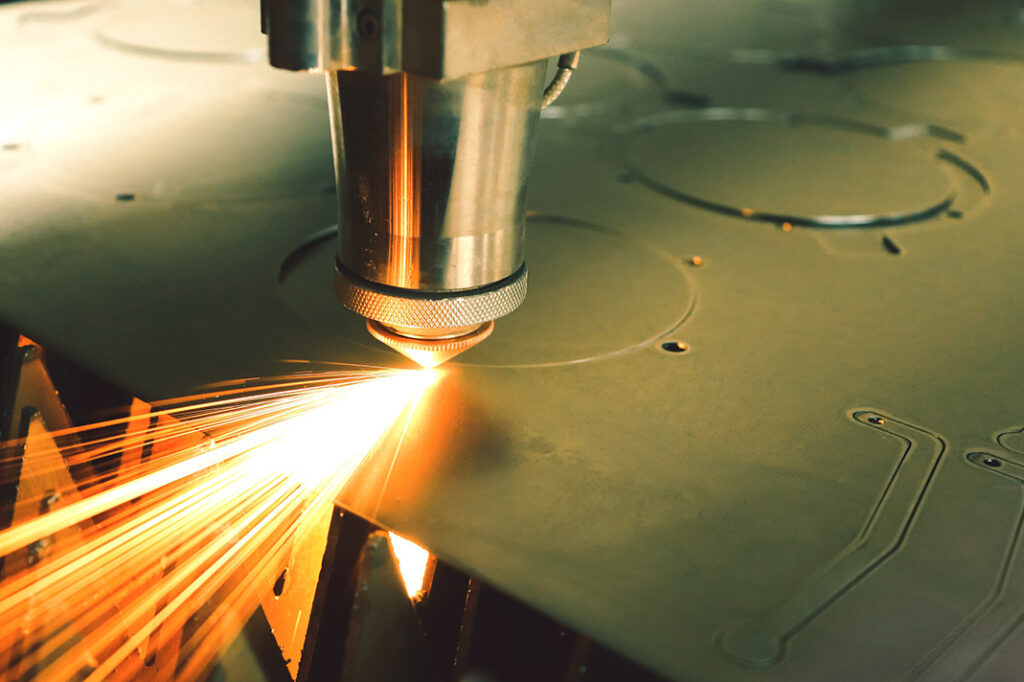

Can Glass Be Cut Through Laser Cutting?

Laser cutting requires special techniques and it works perfectly to cut any kind of materials no matter how hard and light it is, laser cutting is highly versatile. Notwithstanding, laser cutters have the capability to cut the grass easily. They are made to cut glasses and even cut anything, but a few things restrict the laser cutter from properly cutting them.

The reflectiveness of glass poses requirements to the power of your laser cutting equipment. Additionally, the cutter should have a cooling framework. Really at that time, might the machine operator at any point have full command over the bearing of the crack at each progression, bringing about a proper completion.

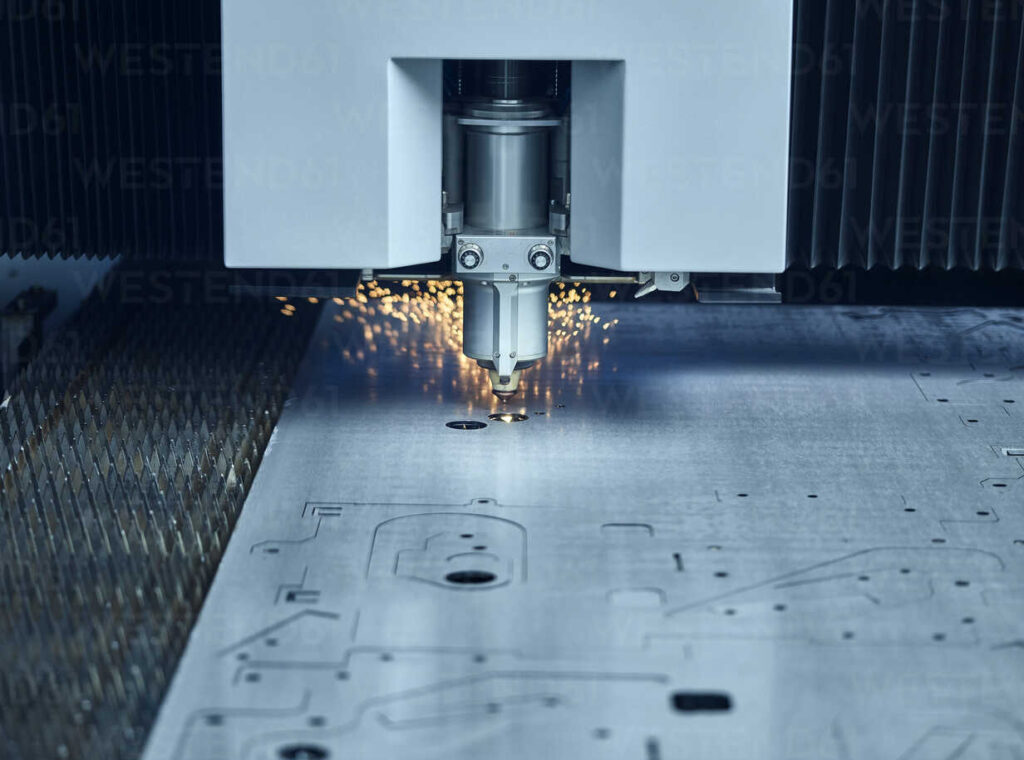

What Are The Advantages Of Laser Cutting?

Source: 3dwholesale.com

Until now, you know what materials shouldn’t be cut by laser cutting and the materials that are best suited for laser cutting. Further, we will talk about what are the advantages of laser cutting and why you must know about them. If you are using a certain type of cutting, it is crucial for you to know what makes laser cutting important and advantageous.

Quality And Cost-Effectiveness:

Plasma or water was generally viewed as a more easier way of cutting than laser cutting, but these techniques don’t live remotely close to the nature of a laser cut. Laser cutting is known for providing good quality cutting at a reasonable rate. In any case, the upgrades in power, effectiveness and innovation mean laser cutting can coordinate or even override the worth of alternative strategies. Recently, laser cutting is becoming preferable because of its advantages along with effective and exceptionally good results.

It relies upon the complexities of the requirement; however, laser cutting is faster and cleaner, with less heat bending or distortion, and that implies there is less to do after it is cut, more straightforward to work with and prepared for our client to utilize. Laser cutting ensures to give you the expected result at affordable prices.

Can Handle Jobs Of Almost Any Complexity:

There is no work that is excessively complicated for a laser shaper. The powerful laser can chip away at an extremely restricted segment of material and make next to no distortion or warping in the region being cut. Complexity does not limit the ax cuts as they can work almost on everything.

With the legitimate schematic, co2 laser machines can be utilized to rapidly and effectively make even the most profoundly complex calculations and cuts with unmatched accuracy and astounding resistance levels.

Low Power Consumption:

While the laser used to cut materials utilizes a lot of energy, laser cutters have no other moving parts – not at all like presses and a few other cutting devices, which require gigantic measures of energy to cut a particular item. Even if a material requires a lot of energy, the laser cutter will ensure that the least amount of energy should be used.

There are many different types of cutting equipment in the market that use quite a lot of energy. However, laser cutters seldom require in excess of 10 kW of energy — in any event, when they are being utilized to cut very thick, intelligent materials like aluminum. They use a sufficient amount of energy and provide the expected result.

Parting Words:

This article consists of all the things related to laser cutting so in future if you are in a state of dilemma do check this one out. This will work for you as a guide and will have comprehensive knowledge about the laser cutting technique and why you must use it.